Why Eye Protection Matters

Around 90% of all workplace eye injuries can be prevented with proper protective equipment. Yet eye protection is often overlooked—with potentially serious consequences. Whether mechanical, chemical, or thermal hazards: our eyes are sensitive, and many risks can be significantly reduced with the right eyewear.

European Standards: What Really Counts

Safety glasses must meet strict requirements and be certified according to European standards. The most important ones include:

- EN 166 – The basic standard for personal eye protection. Covers optical quality, mechanical strength, protection against liquids, dust, radiation, and more.

- EN 169 – For welding filters, such as welding goggles or helmets with protective filters.

- EN 170 – UV filters, e.g., for outdoor work or work involving UV light sources.

- EN 172 – Protection against solar radiation for industrial use (not for road use).

All safety glasses must also be CE-certified to be approved as personal protective equipment (PPE) in Europe. All our models are CE-certified.

Different Types of Safety Glasses – and Their Applications

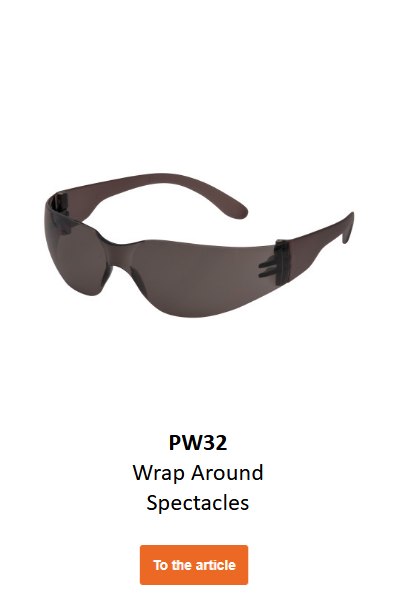

1. Standard Safety Glasses

These versatile models resemble regular glasses but offer additional protection via side shields or special frame designs. They are lightweight, comfortable, and often compatible with prescription glasses. Ideal for:

- Wood and metalworking

- Construction and installation work

- Tasks involving compressed air or flying particles

2. Welding Goggles

These specialized goggles protect against extremely bright light, UV and infrared radiation, and flying sparks. Depending on the welding process, different protection levels (DIN ratings) are required. Welding goggles are a highly specific form of protection and are also available in flip-up designs.

Typical applications:

- Oxy-fuel welding

- Grinding

- Flame cutting

3. Face Shields / Visors

A visor protects not only the eyes but the entire face—ideal for especially hazardous tasks or chemical exposure. This large-area protection can be combined with respirators or helmets.

Typical applications:

- Chemical and laboratory work

- Using grinders or chainsaws

- Metal casting and high-temperature tasks

Choosing the Right Protection – For Long-Term Safety

Whether it's debris, sparks, fumes, or light radiation—there's a suitable safety eyewear option for every hazard. What matters is not only wearing comfort, but also strict compliance with standards and selecting the right type of protection for each task. By protecting yourself and your team properly, you're investing not just in safety, but in long-term health.