In highly sensitive manufacturing environments, uncontrolled electrostatic discharge (ESD) can cause enormous damage – to people, products, and machines. ESD gloves are the solution: They reliably prevent charging and discharging, thus ensuring the highest quality at every stage of production.

Certification is crucial. The following is an overview of the most important norms and standards for ESD gloves:

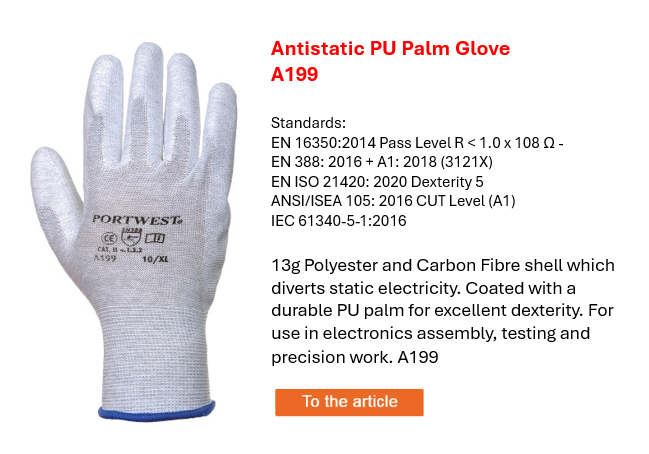

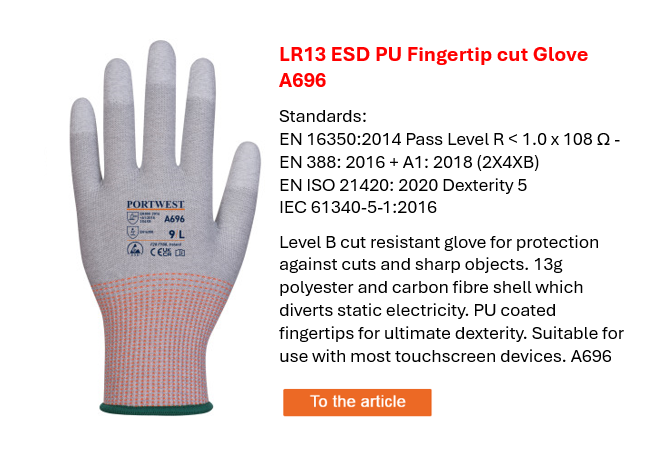

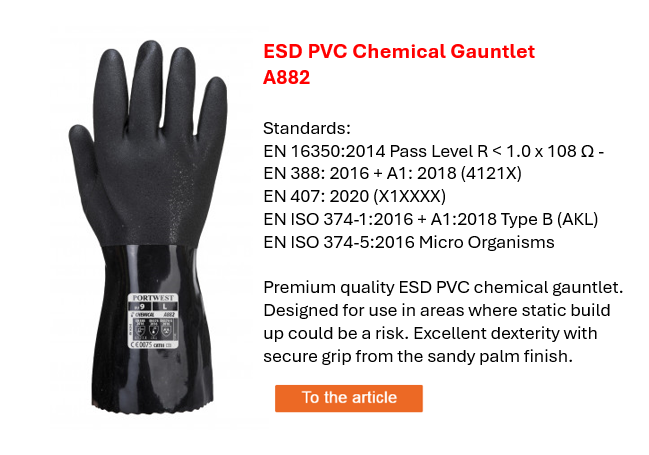

- EN 16350:2014: Certifies the electrostatic conductivity of the gloves. A surface resistance of less than 1.0 × 10⁸ ohms guarantees that charges are safely dissipated – essential for ESD-protected areas (ESD-protected areas).

- EN ISO 21420:2020: Ensures comfort, ergonomics, and maximum dexterity. Dexterity Level 5 ensures precise handling of the finest components.

- IEC 61340-5-1:2016: Specifies comprehensive requirements for the protection of electronic components against electrostatic discharge. Compliance is mandatory for all electronics companies.

- EN 388:2016 + A1:2018 (3121X): Mechanical protective properties such as abrasion, cut, tear, and puncture resistance are tested here. The "3121X" profile demonstrates good abrasion resistance and flexibility – ideal for precise work. This standard is not mandatory in the context of ESD, but many gloves are certified according to it and offer an additional function.

Typical application sectors:

- Electronics industry: Printed circuit board assembly, semiconductor manufacturing, sensor technology

- Automotive: Manufacturing of electronic vehicle systems

- Medical technology: Manufacturing of sensitive diagnostic and therapeutic devices

- Pharmaceutical industry: Protection of sensitive substances from ESD

- Aerospace: Manufacturing of electronic systems for navigation and control

ESD gloves that meet all relevant standards are an essential investment in safety and quality. They guarantee controlled work environments, reduce failure rates, and strengthen your customers' trust – a competitive advantage that pays off.